Get Electrostatic Metal Painting

Electrostatic metal painting services help property owners achieve durable, smooth finishes on metal surfaces for projects like fences, gates, railings, and industrial equipment.

Electrostatic metal painting services offer an efficient and durable solution for property owners seeking to enhance the appearance and longevity of metal surfaces. This specialized technique uses electrostatic technology to apply paint evenly and tightly, reducing overspray and ensuring a smooth, high-quality finish. Property owners in the area might explore this work to improve the aesthetic appeal of fences, gates, railings, or industrial equipment, while also providing added protection against corrosion and wear.

When planning a project involving metal surfaces, it’s helpful to compare local contractors who specialize in electrostatic painting. Working with experienced service providers can ensure the job is completed with attention to detail and quality standards. Property owners are encouraged to explore their options and connect with local professionals who can provide the expertise needed to meet their specific project requirements.

- Industrial Equipment - when machinery or tools require a durable, electrostatic coating to prevent corrosion and improve longevity.

- Commercial Fixtures - for businesses seeking a sleek, protective finish on display cases, shelving, or other metal fixtures.

- Architectural Metalwork - when buildings or structures need a high-quality electrostatic paint application to enhance appearance and durability.

- Automotive Parts - for auto repair shops or manufacturers needing electrostatic painting on vehicle components for a smooth, lasting finish.

- Custom Metal Projects - when unique or decorative metal items require specialized electrostatic coating to achieve a professional look.

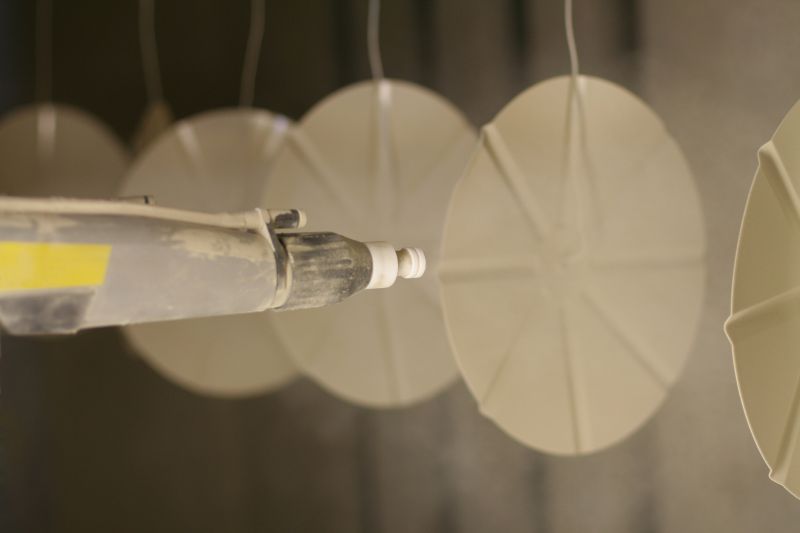

Electrostatic metal painting is a specialized coating process that applies paint to metal surfaces using an electrostatic charge. This technique involves charging the paint particles so they are attracted to the grounded metal surface, resulting in a smooth, even coating with minimal overspray. The process is efficient and provides a durable finish that adheres well to various types of metal, including steel, aluminum, and iron. It is commonly used for both residential and commercial projects to enhance the appearance and longevity of metal fixtures, furniture, or structural components.

This service helps address common problems such as rust, corrosion, and surface deterioration that can compromise the integrity and look of metal surfaces. Over time, exposure to the elements can cause metal to weaken or develop unsightly rust spots, especially on outdoor fixtures like gates, fences, or railings. Electrostatic painting offers a protective layer that prevents further corrosion and extends the lifespan of metal items. Additionally, it provides a clean, professional appearance that can improve curb appeal and property value.

Properties that often benefit from electrostatic metal painting include residential homes with metal fences, gates, or railings, as well as commercial buildings with metal fixtures or structural components. Industrial facilities may also use this service to coat machinery and equipment. Homeowners who want to refresh or upgrade the look of metal features, or those seeking to prevent rust and damage, can find this service especially useful. It is a practical option for those looking to maintain the durability and aesthetic appeal of their property's metal elements.

When considering electrostatic metal painting, property owners should look for local service providers experienced in this technique. These professionals can assess the condition of existing metal surfaces, prepare them properly, and apply a high-quality coating that meets specific needs. Whether restoring old metalwork or finishing new installations, connecting with local contractors ensures the work is performed efficiently and to a high standard. This service can be a valuable solution for enhancing both the appearance and longevity of various metal features around a property.

The overview below groups typical Electrostatic Metal Painting projects into broad ranges so you can see how smaller, mid-sized, and larger jobs often compare in your area.

In many markets, a large share of routine jobs stays in the lower and middle ranges, while only a smaller percentage of projects moves into the highest bands when the work is more complex or site conditions are harder than average.

Smaller Repairs - Typical costs for minor electrostatic metal painting jobs, such as touch-ups or small panels, generally range from $250-$600. Many routine projects fall within this middle tier, though prices can vary based on size and complexity.

Medium-Sized Projects - Mid-range projects involving larger sections or multiple areas often cost between $600-$2,000. These are common for residential or commercial upgrades and tend to be the most frequently completed jobs by local contractors.

Large Installations - Larger, more complex projects, such as extensive metal wall treatments or entire building facades, can range from $2,000-$5,000 or more. Fewer projects push into this higher tier, which typically involves detailed preparation and multiple coats.

Full Replacement - Complete metal surface replacements or major overhauls can exceed $5,000 depending on size and scope. These are less common and usually involve significant surface prep, custom finishes, or specialized techniques.

Actual totals will depend on details like access to the work area, the scope of the project, and the materials selected, so use these as general starting points rather than exact figures.

Powder Coating - This process involves applying durable coatings to metal surfaces, utilizing electrostatic application techniques similar to electrostatic metal painting.

Industrial Metal Finishing - Professionals in this field use specialized tools and planning to achieve smooth, protective finishes on large metal components.

Metal Surface Preparation - Preparing metal surfaces for painting or coating requires skills in cleaning, sanding, and priming, paralleling the surface prep involved in electrostatic painting.

Automotive Painting - Automotive painters use electrostatic spray guns and techniques comparable to those used in electrostatic metal painting services.

Architectural Metal Coatings - Applying protective and decorative coatings to building exteriors involves planning and tools similar to electrostatic painting methods.

Electrostatic Spray Painting for Appliances - This specialized painting process uses electrostatic charge to evenly coat appliances, closely related to metal painting techniques.

When comparing service providers for electrostatic metal painting, it's important to consider their experience with similar projects. Homeowners should look for local contractors who have a proven track record of handling projects comparable in scope and complexity. Asking about the types of surfaces they've painted and the materials they've worked with can provide insight into their familiarity with electrostatic techniques and their ability to deliver quality results. An experienced professional will be better equipped to anticipate potential challenges and recommend the most effective solutions for your specific needs.

Clear, written expectations are essential to ensure both parties are aligned on the scope of work, materials, and finishes. Homeowners should seek out local service providers who can provide detailed estimates and project descriptions in writing. This documentation helps prevent misunderstandings and sets a foundation for a smooth project. A reputable contractor will be transparent about what is included, any potential additional costs, and the steps involved, giving homeowners confidence in the process and the final outcome.

Good communication and reputable references are key factors when choosing a local contractor for electrostatic metal painting. Homeowners should inquire about references from previous clients who had similar work done, as these can offer valuable insights into the contractor’s professionalism and quality of work. Additionally, responsive and clear communication throughout the selection process indicates a contractor’s commitment to customer service. While the site introduces homeowners to local options, it’s important to evaluate each service provider’s experience, clarity in expectations, and communication style to find the best match for the project.

Property owners use Electrostatic Metal Painting services for practical projects around their homes and businesses. This guide focuses on everyday jobs and straightforward project options.

Electrostatic metal painting is a practical solution for property owners who need to refresh or upgrade metal surfaces such as fences, gates, railings, or outdoor furniture. When these items become worn, chipped, or rusted, local contractors can provide a durable and uniform finish that enhances the appearance and extends the lifespan of the metal. This service is often sought after during home renovations, property maintenance, or when preparing a property for sale, helping owners maintain a polished and well-kept exterior.

Property owners might also look for electrostatic metal painting services to improve safety and security features around their property. For example, metal fences or barriers that have lost their protective coating can be more vulnerable to corrosion, which can compromise their integrity. Local service providers can restore these surfaces with a high-quality finish, ensuring they remain functional and visually appealing. Whether updating existing features or completing new projects, many rely on nearby contractors to handle these specialized painting needs efficiently.

What is electrostatic metal painting? Electrostatic metal painting is a process that uses electrically charged paint particles to evenly coat metal surfaces, resulting in a smooth and durable finish.

Which types of metal surfaces can be painted with electrostatic methods? This technique is suitable for a variety of metal surfaces, including steel, aluminum, and iron, commonly used in industrial, commercial, and residential applications.

Are there specific benefits to choosing electrostatic metal painting? Yes, electrostatic painting provides a high-quality finish with minimal overspray, enhanced adhesion, and increased corrosion resistance on metal surfaces.

How do local contractors typically prepare metal surfaces for electrostatic painting? Preparation usually involves cleaning, degreasing, and sometimes sanding or blasting to ensure proper adhesion of the paint.

What types of finishes can be achieved with electrostatic metal painting? Service providers can apply a variety of finishes, including matte, gloss, and textured coatings, depending on the desired appearance and application needs.

Enhance outdoor metal features - Property owners can improve the appearance and durability of fences, gates, and railings with electrostatic metal painting services.

Refresh interior metal fixtures - Local contractors can help update stair rails, cabinets, and decorative elements inside the home for a new look.

Protect metal surfaces from corrosion - Property owners can extend the lifespan of metal surfaces exposed to weather or moisture through professional electrostatic coating.

Customize metal furniture and accents - Local service providers can assist in applying vibrant or matte finishes to metal furniture, sculptures, or decorative pieces.

If you are thinking about Electrostatic Metal Painting for a property, this guide is meant to help you understand the work, the typical project types, and how different options might fit your plans.

When you are ready, you can use the quote form on this page to share a few details about your project. From there, local pros can review the basics and respond with options that match what you have in mind.